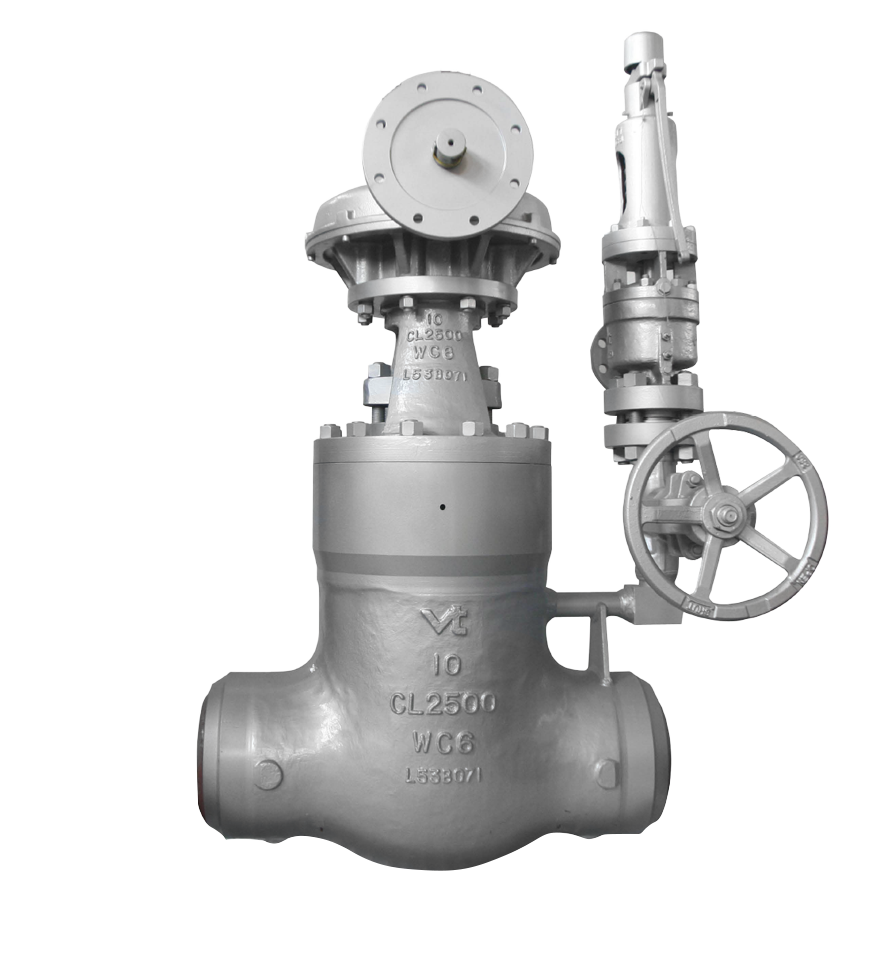

Lubricated Type Plug Valve

SPECIFICATIONS

| Design Standard | : | API 6D / API 599 / BS 5353 |

| Size Range | : | 1/2” – 18” |

| Pressure Rating | : | Class 150 – 600 |

| Working Temperature | : | -29˚C ~ +325˚C -20˚F ~ +617˚F |

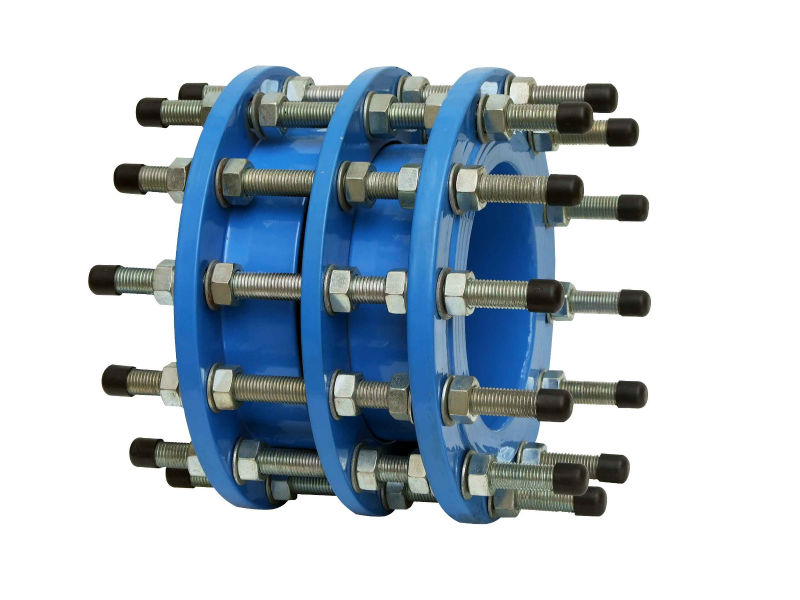

| End Connection | : | ASME B16.5 - Flange ASME B16.25 - Butt-Weld / Threaded End |

| Face-to-Face | : | ASME B16.10 |

| Test & Inspection | : | API 598 / API 6D |

Lubricated taper plug valves are suitable for use in pipelines with various kinds of working conditions, with nominal pressure of Class 150 to Class 600 and working temperature of -29˚C to +325˚C in such industries as petrochemical, chemical pharmaceutical, fertilizer and power plant, etc., to cut off or turn on the flow medium in pipelines.

Grease sealed structure has been adopted for the outlet of the valve body which is especially suitable for the pipelines with grainslurry medium. There is a grease chimb in the plug surface, where the grease gets in with higher pressure than the slurry in pipelines, thus it forms an oil film to isolate slurry with the plug of rest state from getting into the gap between valve core and valve wall, which avoids the rubbing. Under the dynamic state of the plug, it generates high speed oil flow to impact slurry and prevent it from entering the gap. Ensuring normal operation of the plug valves, which enhances the economic functions of slurry pipeline transportation engineering.

Main Features

The tightness is achieved by injecting grease in the seat.

The tightness is achieved by injecting grease in the seat.

There is no cavity in the valve for accumulation of solids in the medium.

There is no cavity in the valve for accumulation of solids in the medium.

The rated temperature for the plug valve depends on the grease used.

The rated temperature for the plug valve depends on the grease used.

The selection of the grease should be the managed based on the pipeline medium.

The selection of the grease should be the managed based on the pipeline medium.

Plug valves are bi-directional simplifying installation and operation

Plug valves are bi-directional simplifying installation and operation

Multiple options of valve flow bore pattern available: regular, venturi, etc.

Multiple options of valve flow bore pattern available: regular, venturi, etc.

Three lubricated plug valve available.

Three lubricated plug valve available.

| Document | Type | Download |

|---|---|---|

| Lubricated Type Plug Valve | English |