Check Valve

SPECIFICATIONS

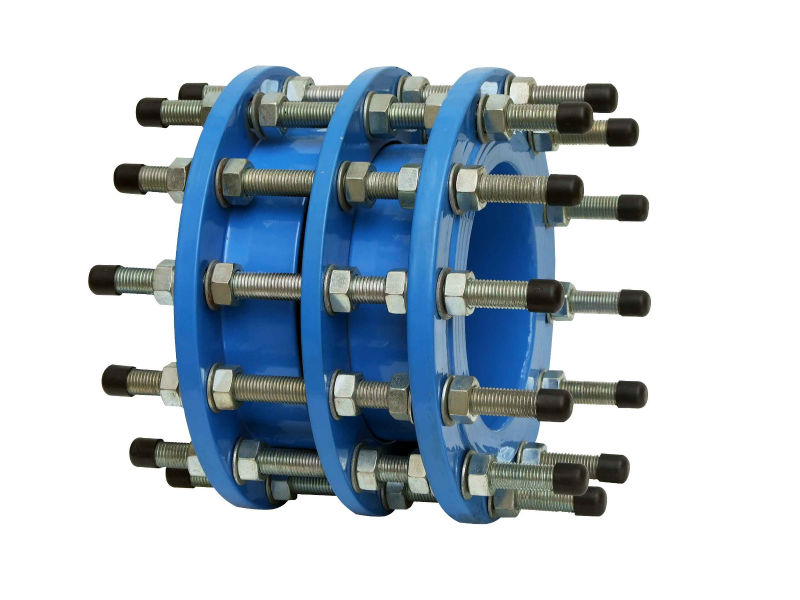

| Design Standard | : | API 600 / API 6D |

| Size Range | : | 2" - 36" |

| Full Bore | : | Full Bore |

| Body Style | : | Bolted Bonnet Pressure Seal Bonnet |

| Pressure Rating | : | 150 psi - 2500 psi |

| Working Temperature | : | -196˚C ~ +650˚C -320˚F ~ +1200˚F |

| End Connection | : | ASME B16.5 / ASME B16. 25 / ASME B16.47 |

| Face-to-Face | : | ASME B16.10 |

| Test & Inspection | : | API 598 / API 6D |

Features

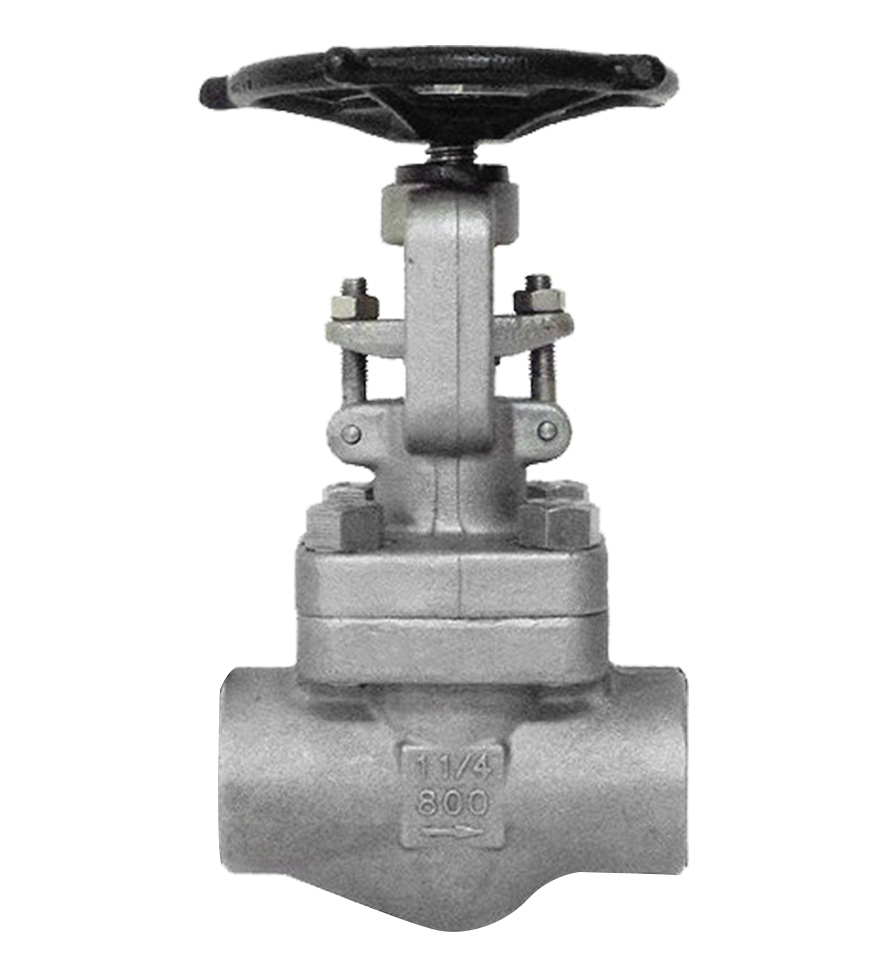

VAHN-TECH manufactures superior cast steel check valves in a variety of designs, materials, trims, sizes 2” - 48” and pressure class 150 to 2500.

Check valves are designed in full compliance with API 6D / API 594. Swing Check Valves, Dual Plates Check Valves and Lift Check Valves are available.

Check valves are designed in full compliance with API 6D / API 594. Swing Check Valves, Dual Plates Check Valves and Lift Check Valves are available.

Body and bonnet castings are precision machined with joint accurately machined.

Body and bonnet castings are precision machined with joint accurately machined.

Carbon Steel, Low temperature Carbon Steel, Stainless Steel, Duplex Stainless Steel as well as nickel and

exotic alloys available.

Carbon Steel, Low temperature Carbon Steel, Stainless Steel, Duplex Stainless Steel as well as nickel and

exotic alloys available.

Check valves option in accordance with API-603 only for stainless steel & nickel alloys

Check valves option in accordance with API-603 only for stainless steel & nickel alloys

Swing Check Valve with top entry design for easy maintenance.

Swing Check Valve with top entry design for easy maintenance.

Check valves for Cryogenic service with gas column in accordance with BS-6364 upon request.

Check valves for Cryogenic service with gas column in accordance with BS-6364 upon request.

Special closing system can be designed on request fro Swing Check valve: slow closing or fast closing swing check valves.

Special closing system can be designed on request fro Swing Check valve: slow closing or fast closing swing check valves.

Flange dimensions in accordance with ASME B16.5 for valves up to 24” nominal diameter and ASME B16.47 for valves 28" and up.

Flange dimensions in accordance with ASME B16.5 for valves up to 24” nominal diameter and ASME B16.47 for valves 28" and up.

| Document | Type | Download |

|---|---|---|

| Check Valve | English |